Services for wind turbines

![]()

It is possible to sustain the operating features of wind turbines and to restore their performance by preventive maintenance. This also helps in avoiding unexpected interruptions in production, equipment damages and expensive repairs.

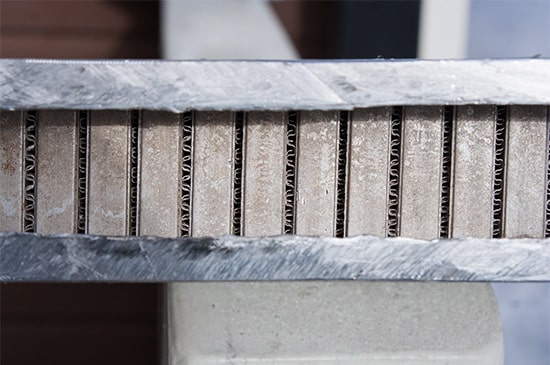

The maintenance of cooling systems in wind turbines is very challenging. This is due to the location of the systems, their inaccessibility and the lack of space. Cleaning and filling the cooling systems and recovering aged coolants are difficult and demanding procedures.

New maintenance methods

We have introduced a new method for the maintenance of cooling systems in wind turbines. This method enhances the cleaning and filling of cooling systems.

We have a well-trained maintenance team which can perform even the most demanding maintenance procedures for the cooling systems of wind turbines. They use special equipment and chemicals developed for this purpose.

Before the cleaning, the condition of each cooling system is investigated by means of laboratory analyses. The customer receives an analysis report on the results, as well as system-specific recommendations. The implementation plan and the maintenance schedule is agreed upon with the customer.

In the maintenance procedures, we use our own heat transfer liquids approved by machine manufacturers.

Limited lifetime of glycols

Heat transfer liquids used in the cooling systems of wind turbines deteriorate in the long run. This leads to contamination of cooling systems. The systems lose their heat transfer capacity, and expensive interruptions may occur.

Deteriorated heat transfer may cause corrosion and result in breakdown of components like frequency transformers. Heat transfer liquids must be changed regularly.

Maintenance of wind turbines

Wind turbines have to be maintained 2-4 times a year, depending on their model and location. Preventive maintenance aims at:

- maintaining the operating capacity of wind turbines

- restoring the reduced performance of wind turbines

- preventing malfunctions in and damages to wind turbines

Partners

We work closely with major manufacturers of frequency transformers for wind turbines. We have received their approval when it comes to using our products and services in their machines.

Our services for wind turbines are as follows

- analyses of circulation liquids in cooling systems

- cleaning and flushing of cooling systems

- filling of cooling systems with anti-freeze chemicals that contain corrosion inhibitors

- ultrasound flow measurements

- endoscopic imaging and maintenance reports

- recycling services for aged glycol solutions

- follow-up agreements