News: KL-Lämpö awarded a Bronze Medal in the EcoVadis sustainability assessment

Glycol-based systems

![]()

Heat transfer, cooling, condensing, snow melting, heat recovery and AHR systems

The maintenance of glycol-based heat recovery and condensing systems is often neglected. The systems are expected to function for as long as there is some heat transfer liquid in them. However, all glycol-based heat transfer liquids disintegrate over time, losing their properties and causing different problems.

The glycol in the system might also be of the wrong type or concentration, which reduces the efficiency. As the glycol disintegrates, its frost-resistant properties are dramatically reduced. Corrosion inhibitors may also lose their efficiency. This speeds up corrosion, causing scale formation and leaks in the system.

System surveys and analytical services

For the above reasons, the condition of glycol-based systems must be monitored and analysed. KL-Lämpö offers comprehensive system surveys and analytical services for the preventive maintenance of glycol-based systems. Our surveys and analyses help determine the condition of the system. The customer also receives system-specific recommendations for future action and a cost estimate for the required maintenance. Regular follow-up analyses are often agreed upon with the customer.

Maintenance and repair services

Pre-commissioning or remediation cleaning and glycol filling

We carry out chemical cleanings of heat recovery and condensing systems. After a thorough flushing, we fill the system with the right kind of glycol-water solution, which contains a corrosion inhibitor. These procedures ensure that the system and its devices work as planned and without interruption.

Verifying the glycol quality

We verify the quality of the antifreeze/anticorrosive agent (monoethylene/monopropylene glycol). This procedure ensures that the capacity of the equipment is sufficient and assures that the heat transfer capacity remains at the planned level. Heat recovery and condensing systems must always contain the type of glycol specified in the original plan – i.e. monoethylene glycol or monopropylene glycol.

Checking the glycol content

The frost resistance capacity and the optimal efficiency ratio are assured by checking the glycol content in the system. The glycol content has to correspond to the value specified in the original plan. The corrosion protection level of the system can be improved by adjusting the corrosion inhibitor content. This procedure extends the lifetime of the antifreeze/anticorrosive agent.

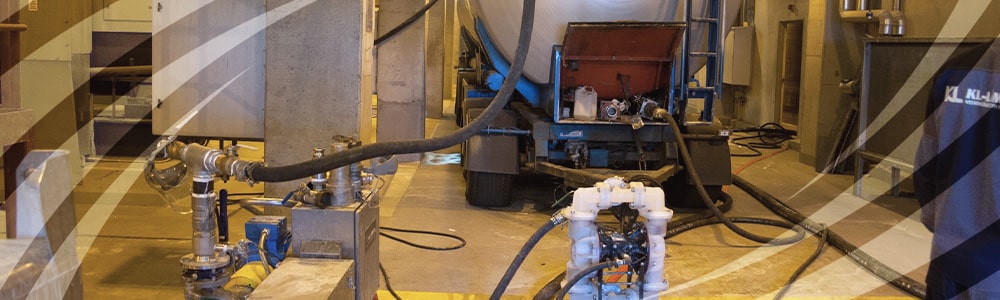

Filtration of solids

Detrimental solids are removed from the system by filtration. Solids may cause blockages and defects in the devices installed in the system. Filtration improves the quality of heat transfer liquids and ensures the smooth operation of devices.

Glycol filling stations

Our product range includes filling stations for glycol solutions. They are equipped with a closed container and an electric pump. Replacing traditional manual pumps, they facilitate the pumping of the glycol and can be used to add pressure, if necessary. They also help keep the reserve glycol clean.

Recycling services for aged glycol solutions

Water-glycol solutions which have been used for heat transfer purposes may contain large quantities of heavy metals. Such solutions are categorized as hazardous waste and must be disposed of according to local regulations.

If the amount of impurities is not too high, used glycol solutions can be recovered, purified and recycled.

For recycling, we accept aged ethylene and propylene glycol solutions, which contain at least 20% glycol and which do not contain any oil.

These solutions are purified and recycled by our partner. The purification process is based on different techniques of filtration and evaporation. Recycled glycol can be re-used in a variety of applications.

Our recycling services include:

- emptying of glycol systems

- recovering and recycling of used glycol solutions

- arranging and archiving the required movement documents

- refilling the systems with long-lasting glycol solutions, which contain a corrosion inhibitor

- analytical and monitoring services

Reporting

The customer receives a report on all the maintenance procedures that have been carried out. The report includes information about the initial situation, the procedures that were implemented, as well as recommendations for future action. The report can be attached to the maintenance manual or the property deed.