News: KL-Lämpö awarded a Bronze Medal in the EcoVadis sustainability assessment

Services for power plants

![]()

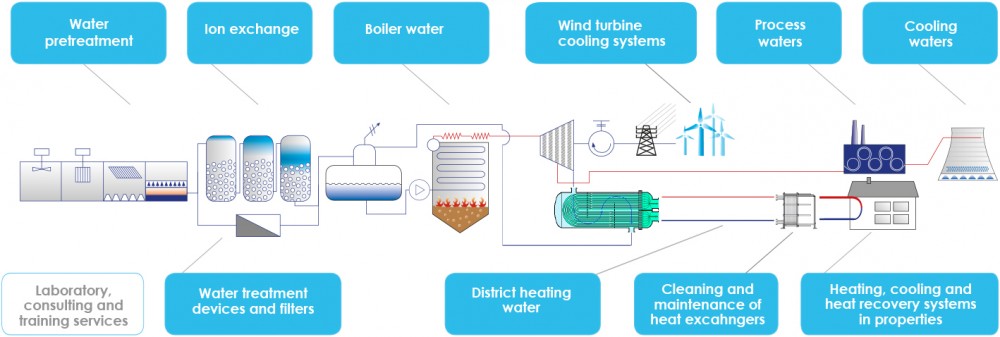

Water treatment services for power plants

There are strict regulations for water treatment in the energy industry to ensure that power plants run economically and without interruption. Well-managed water treatment plays an important role in the preventive maintenance of power plants.

KL-Lämpö’s water treatment services ensure that the energy production and energy transfer processes at powerplants work optimally and according to set requirements. Our customers in the energy industry include steam power, district heating and power generation plants as well as wind turbines.

We serve power plants in the production of makeup water, in the pretreatment of water and at various stages of steam generation and utilization. Our comprehensive product range for district heating plants includes for example water treatment chemicals and equipment.