News: KL-Lämpö advances its climate work through the Climate Program

Energy Industry Services: Boiler corrosion and deposits – How to manage both system pH and conductivity?

23.05.2016

By Pekka Ojala, Product Group Manager, KL-Lämpö Oy

Boiler circulation control depends mainly on two factors: pH and oxygen (redox potential). Chemicals are needed to maintain adequate control parameters. Thus, also conductivity is raised. How to simultaneously reach these two controversial goals?

Increased turbine efficiency has led to tighter steam conductivity requirements. On the other hand, chemicals are needed to maintain high enough system pH. Consequently, also conductivity will raise.

Goals

The goal of the program development was to reach the parameters set by SKY 1):

1. Steam pH 9,2 - 9,6.

2. Degassed cation conductivity

< 0,03 mS/m (0,3 µS/cm ).

3. Minimize the organic acids in the circulation.

4. Low circulation iron levels

(< 10 µg/l).

1) Vesikemian ohjearvot, Suomen Soodakattilayhdistys ry 9.12.2011

(Boiler Water Chemistry Guidelines, Finnish Recovery Boiler Association)

Conclusions

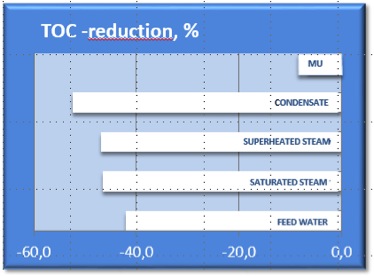

While dosing chemicals for the need only, these goals may be reached. In most cases the need of oxygen scavenger is relatively low. By choosing right buffering amines high enough system pH is reached, still not jeopardizing the low conductivity target. As a result of the boiler chemistry modification:

1. The superheated steam organics were reduced; TOC 0,78 → 0,39 mg/l.

2. Organic acid concentrations went down below detection level (< 10 µg/l).

3. Degassed cation conductivity of steam reduced (turbine steam 0,04 → 0,03 mS/m).

4. Iron levels 5. The dosage needed for the same pH level reduced, i.e. less cost.